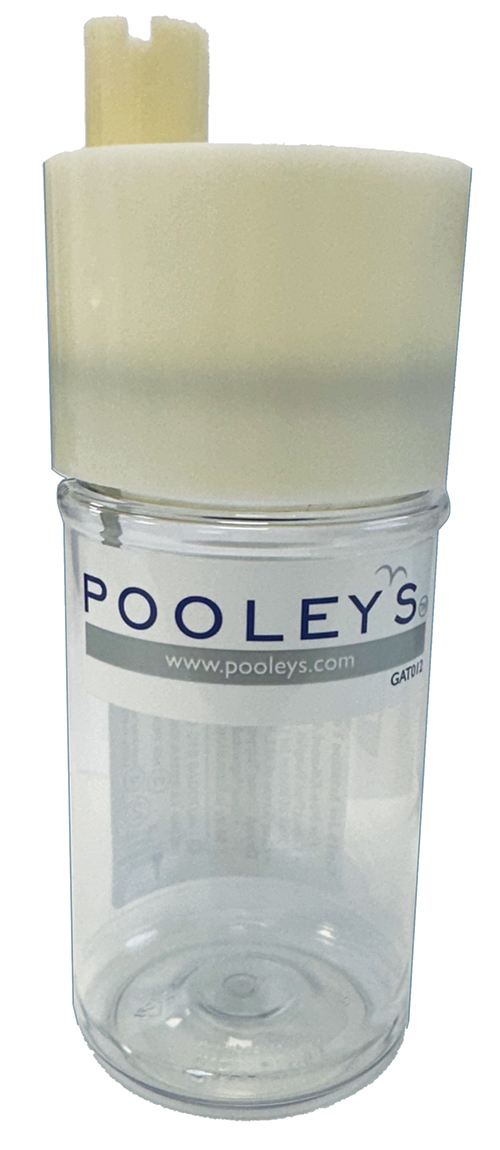

The GATS Jar / Fueltester

Note: Catch all fuel samples in the GATS jar. Never discharge fuel from your aircraft onto the ground.

- Check the condition of the separator screen for tears, larger than normal holes or damage of any kind.

- Select the appropriate sump valve actuator tip.

- Draw, examine and retain all fuel samples in the normal course of the pre-flight inspection, observing colour for proper octane.

- Check for water sitting on the top surface of the separator screen. Use a by-pass hole to get any excess water droplets inside the separation jar.

- Clean the top surface of the separator screen with a dry, absorbent tissue or cloth. Warning: Before proceeding to the next step see that the actuator assembly is firmly seated and will not fall out of the separator assembly while the tester is being tipped or else remove it altogether, while the fuel is being poured back into the aircraft, to avoid dropping the actuator into the fuel tank.

- While visually checking the last fuel tank level, pour all the collected fuel samples back into the aeroplane’s fuel tank, through the separator screen in the GATS jar, taking care not to tip the GATS jar too far, thereby over-pouring the separator screen.

- Pour the water that has been separated out and trapped in the collection jar onto the ground through one of the by-pass holes.

- AVGAS users only - Gently blow on the separator screen for at least 30 seconds observing the evaporation of the sample fuel from in between the screen fibres. Except for any water drops, all screen openings should be free of liquid within about 60 seconds. After the initial wave of evaporation the remaining fuel trapped in the screen openings is most likely to be jet fuel, or some other inappropriately heavy fuel.

Note: If only one fuel tank is refuelled, test the tank for jet fuel contamination separately.

| Hersteller / Verlag: | Pooleys |

|---|---|

| Material: | Plastic |